News

Analysis of the impact of car supply chain of car chip IDM large manufacturers

Vehicle IDM manufacturers have expanded production

At present, the chip industry is undergoing a downward cycle, and the large manufacturers are still actively expanding production.Recently, the four IDM factories of Yingfeeling, Ruisa, Texas Instruments, and Rapidus have disclosed the latest factories.According to the Taiwan Economic Daily, the industry estimates that the amount of four major factories in expanding production will reach US $ 25 billion.

Yingfeeling has been approved to build a chip factory worth 5 billion euros ($ 5.35 billion) in Germany, which is planned to be put into production in 2026.Ying Feeling said that this will be the largest single investment in its history. The factory will produce power semiconductors and simulation/hybrid signal components.Regarding the establishment of the factory, Jochen Hanebeck, CEO of Yingfei Ling, said that the new factory mainly sees the demand for the semiconductor market of renewable energy, data centers, and automobile electrification, and is showing structural growth.

Source: Yingfei Ling official website

Ruisa Electronics stated that the inventory of automotive products is still lower than the company's target level. In order to reduce the risk of supply chain interruptions for car manufacturers and other important customers in the future, it is considered to expand chip production capacity outside Japan.

Texas Instruments plans to build a second 12 -inch semiconductor wafer manufacturing plant in LEHI, Utah, USA, which is part of the company's $ 11 billion investment in Utah.The new factory is expected to join the existing 12 -inch wafer manufacturing factories in Texas instruments. It is expected to begin construction in the second half of 2023, and is first put into production in 2026.

Source: Texas Organ Website

Rapidus, a chip company supported by Japanese countries, is considering building the first manufacturing plant in Hokkaido, Japan. The earliest decision to be officially decided at the end of February.

In addition to these chip factories, Italian semiconductor, Intel, Wolfspeed, Bosch, etc. either disclose the expansion plan, or new factories have been under construction.

On August 4, 2022, the Semiconductor Semiconductor signed a business and cooperation agreement with GlobalFoundries. It established a new joint operation of 300 mm semiconductor manufacturing factories near the current 300 mm factory in Crolles, France.-SOI or completely exhausted product of insulators.In October, ST announced that it will build an integrated silicon carbide (SIC) substrate manufacturing plant in Italy, which will become the first factory in Europe to mass -produce 150mm SIC proliferation.The Italian government will invest 730 million euros to the factory within five years under the framework of the national recovery and recovery plan.

Data source: Saicular Semiconductor Official Website

As early as mid -March 2022, the first stage of Intel's announcement of its IDM2.0 plan was that it invested as much as 80 billion euros in the entire semiconductor value chain in the next ten years.In the initial stage, Intel plans to build two first -class semiconductor factories in Magdeburg, Germany. It is expected to begin construction in the first half of 2023. It is put into production in 2027. The project is expected to cost a total of 17 billion euros.However, the cost of energy and raw materials caused by the energy and raw material costs caused by the energy crisis in 2022, in December 2022, Intel announced that it would postpone plans to open a chip factory in Germany in 2023.In the United States, Intel also announced the newly -built wafer fabry plan for tens of billions of dollars.For example, invested $ 20 billion to build two wafer fabry factories in Arizona, USA; investment of $ 20 billion to build two wafer fabry plants in Ohio, USA, and a total of eight wafer factories will be built in the future.

Wolfspeed announced that it will spend $ 3 billion to plan to build a highly automated 200mm SIC wafer manufacturing plant in Salle, Germany.

In 2022, Bosch invested over 400 million euros to expand its wafer fabal factory (main) in Germany's Dresden and Roytelinen and the semiconductor testing center in Penang, Malaysia. In 2022, the production capacity of the plant will be further increasedEssenceAmong them, the Dresden Wores began to produce 300 mm wafers in July 2022. It was six months earlier than the original plan. It was first used for Bosch electric tools.The chip facing car customers began to produce in September, three months earlier than the original plan.About 50 million euros in 2023 will be used to build the Roytelintone Wanes, which are adjacent to Stuttgart.

In October 2022, Micron, a large storage chip factory, announced that it will spend $ 100 billion in the next 20 years to build a large -scale wafer plant in New York State in the United States to accelerate the development of the United States semiconductor manufacturing.

Source: Micron's official website

Onsemi, a large chip factory, also officially took over the 12 -inch wafer factory in New York State in New York, USA, and held a ribbon -cutting ceremony.The total cost of the wafer plant is $ 430 million.Anssem President Hassane El-Khouse said that the factory "chips that support electric vehicles, electric vehicles and energy infrastructure."

Source: Ansonmei Official Website

Behind production: subsidy, profit and demand

The current prosperity of the chip industry continues to be sluggish, and the once -hot wafer manufacturer cannot be alone.On the other hand, the chip manufacturers have expanded new plans to endlessly, and they are committed to building their own wafer manufacturing plants.Havivilan, the current executive vice president and the current executive of the president and CEO of Texas Instrument and CEO, even said: "Now it is the best time to further expand its own manufacturing capabilities." Why is this?Taken together, the big manufacturers may be based on the following considerations:

From the perspective of policy level, based on national A full, political risks and ideology, some countries seeks diversified suppliers, near -shore and friendly production, and the global industrial chain presentation has evolved from global collaboration to local collaboration.Nowadays, the intention of building a local complete industrial chain in various regions is more clear. Among them, the United States and Europe regards advanced wafers as the key to reviving the chip manufacturing industry, and promulgate the bill to improve chip manufacturing capabilities.

In the past two years, the European Union is seeking to strengthen semiconductor production.On January 24, 2023, the European Chip Act was officially passed.The bill is planned to invest 43 billion euros to support the development of chips. More than two -thirds of the funds are designated to build new, leading chip manufacturers, or "large wafer factories".Investment in IDM plants such as Yingfei, Semiconductor, and Intel is essential for the achievement of the EU's goals, that is, it has reached 20%of global semiconductor manufacturing before 2030.The European Commission has allocated funds of 15 billion euros for public and private semiconductor projects by 2030. This provides unique opportunities for development in Europe. This measure not only attracted EU member states, but also attracted some other large semiconductors.The manufacturer went to Europe to build a factory.

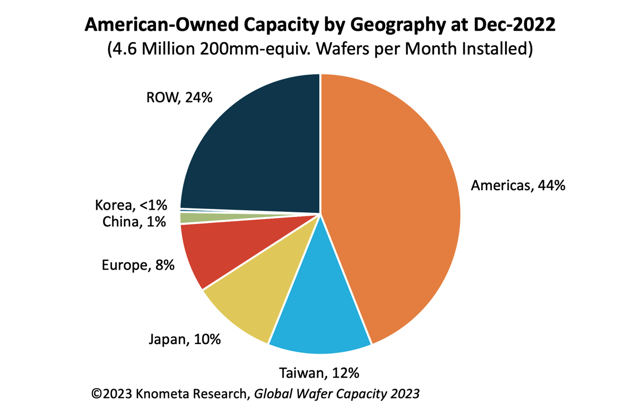

The offshore production status of the US semiconductor industry is even more prominent.Another report released by Knometa Research recently showed that as of the end of 2022, the monthly production capacity of US companies was 4.6 million pieces of 200 mm. Among them, 2 million pieces were produced in the US wafer fab and 2.6 million pieces were produced overseas.In other words, 56% of the wafer production capacity of American chip manufacturers is built outside the United States.Among them, the largest offshore production capacity of American companies is distributed in Singapore (22%of the total), Taiwan (12%), Japan (10%), Germany (4%), Ireland (3%) and Israel (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%) (2%)To.Micron, a storage chip manufacturer, is the largest offshore capacity owner in the United States so far.The company operates 12 wafers outside the United States, accounting for 65%of the total number of wafers produced in the United States.GlobalFoundries ranked second with a 14%share, followed by Intel 9%, and Texas instruments accounted for 5%.

In December 2022, the United States was divided by geographical production capacity

Source: Knometa Research

In order to improve this situation, the United States has proposed ambitious semiconductor goals: by the end of this century, the United States will have at least two new large -scale cutting -edge logical factories clusters.In July 2022, more than 52 billion US dollars of "Chip and Science Act" was approved. This move has promoted the wafer process manufacturers such as TSMC, Samsung, Intel, Micron, Gexin to increase investment in the United States.It is expected that in the future, with the opening of the new wafer fab, the production capacity of wafer manufacturing in the United States will be greatly improved.

With the stimulation of the precision policy of the United States and Europe on semiconductor manufacturing, this means that local wafer manufacturing plants are expected to enjoy more financial subsidies, which has promoted the global IDM chip manufacturer's crazy expansion of production.

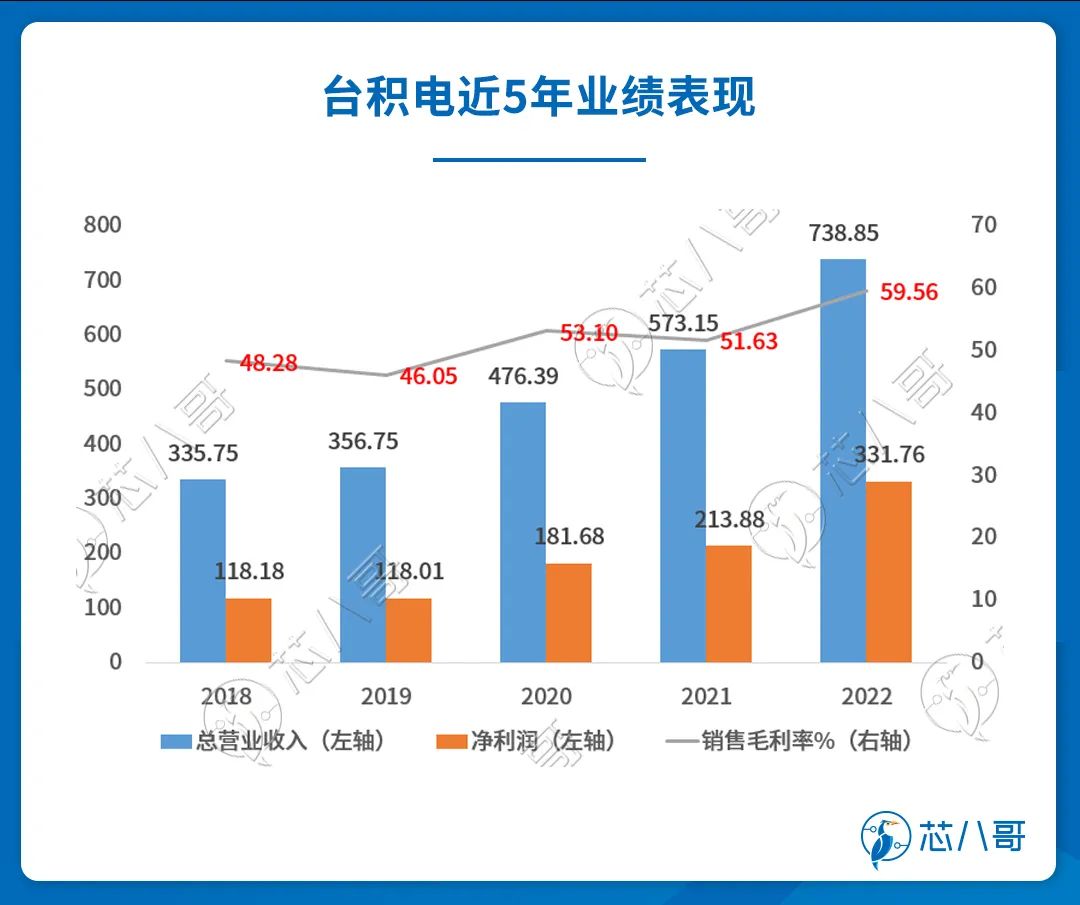

Secondly, the wafer foundry sector enjoys the high bargaining power caused by the shortage of production capacity in the past two years. Whether it is a chip design company that has just experienced the "increase in price and grab production capacity", or the IDM manufacturer who has released a large number of outsourcing orders, none of them are none of them.Do not recognize the value of the manufacturing end.Taking the wafer foundry giant TSMC as an example, compared with 2019, TSMC has doubled its revenue in 2022, and the net profit has doubled, and the gross profit margin has reached nearly 60 %.

Data source: TSMC's financial report, Wind

In addition, it takes 2-3 years from the launch of the wafer factory to the production to put into production. The semiconductor prosperity may be out of the "dark moment" during this period.At the January financial report conference, Wei Zhe, the CEO of TSMC, said, "We expect the semiconductor cycle to bottom out in the first half of 2023 and see a healthy recovery in the second half of this year." In addition, Morgan Stanley expects thatThe second half of 2023 will be an important time point for the semiconductor to start the recovery cycle.A recent research report released by Countpoint shows that the global chip industry currently shows periodic periodic rather than structural weakness. It is expected that the market will be sluggish in the first half of 2023, but it is expected that by the second half of 2023, as OEM manufacturers begin to supplement inventory and inventory andIt is expected that the market is expected to usher in recovery growth.

In other words, the capacity of these expanded production during the trough of the industry is expected to gain rich profits in the next round of the semiconductor industry.

Expansion of production will reshape the car supply chain

So, what impact will the expansion of many large chip factories bring?

Judging from the results of the 2021 automotive semiconductor market statistics released by the research institution semiconductor intelligence (SI), most of these expanded chip factories are mostly large -length IDM chip manufacturers.In the global car chip market, Yingfei Ling is the leader in the industry. Ruisa Electronics and Texas instruments ranked third and fourth, ranking seventh.

Data source: si

Therefore, the crazy expansion of these IDM chip large manufacturers will shorten the delivery process and delivery cycle of the vehicle chip, and alleviate the tension of the shortage of vehicle chips.According to the analysis data from Autoforecast Solutions, the automotive industry data forecast company, as of the end of November 2022, the global automobile industry has reduced the production of 4.1176 million vehicles due to the lack of cores. It is expected that the annual production capacity will reach approximately 4.4853 million vehicles.There are also many non -car products overlapping with the international IDM factory, and they will also face competition in the future.

Changes in the relationship between automotive semiconductor supply chain

The relationship between the new car semiconductor supply chain from the traditional one -way supply to the two -way connection between OEM and Tier1 and Tier2

Not only that, with the launch of subsequent production capacity, it will also effectively meet the demand for the surge in semiconductor in the smart car era.Assume that the semiconductor chip required by traditional cars is 500-600 chips/vehicles, and the semiconductor chip required for new energy vehicles is 1000-2000 chips/vehicles.According to data released by Hisilicon's 2021 China Automobile Semiconductor Industry Conference, the global automotive semiconductor market in 2021 is about $ 50.5 billion. It is expected that the total amount of automotive semiconductor market will be close to $ 100 billion in 2027. The growth rate of 2022-2027 will remain above 30%or more.Essence

Car Electronics occupy a total cost percentage of vehicles

Source: 2021 China Automobile Semiconductor Industry Conference, Hisilicon

Secondly, the expansion of the production of the large IDM chip factory is expected to prevent the car manufacturer from directly looking for the fabric agency to cooperate.In recent years, in order to shorten the over time, the car manufacturers have begun to contact and cooperate directly with the wafer foundry, especially the design of the next -generation vehicle chip is more complicated, and it also requires higher or special semi -guide system support.With the large -scale expansion of vehicle IDM chip manufacturers, car manufacturers will re -evaluate the value of the supply chain.These high -ranking car IDM chip manufacturers have been deeply cultivated in this field for decades. The product category is very rich, which is difficult to compare with the car company's core team.In addition to MCUs for vehicles, car chips also include AMP, IGBT, MOSFET and other power devices, sensors and separate devices.In addition, not only is the car -level chips rich in types, but also high technical barriers. The lengthy certification cycle has made many manufacturers look forward to it.Therefore, compared to the vehicle factory's own chip and cooperating with the wafer factories, the traditional IDM chip manufacturer's direct expansion of production is more obvious.

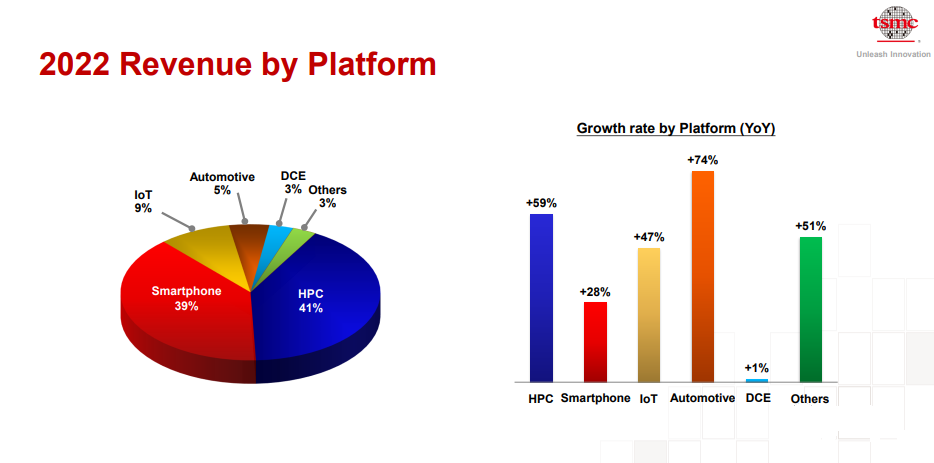

The above -mentioned impacts are directly or indirectly pointing to the wafer factories.Yingfei, Ruisa, Texas instruments, and Ansonami all designed chips and have a large IDM chip factory with their own wafer fab, and have many products such as IC and MCUs.Production, but many products are commissioned by wafer foundries such as Tenjack and UMC.With the construction of these IDM factories, it will inevitably cut off -commission orders and adversely affect the wafer foundries such as TSMC and UMC.Taking TSMC as an example, in 2022, the automobile business accounted for 5%, and the growth rate was as high as 74%, most of which came from the outsourced foundry of the vehicle IDM plant.If the production capacity of the large IDM chip plant is increased, the wafer agency factory such as TSMC may lose some orders.

In 2022, the proportion of income and growth rate of various parts of Tanjician's business

Source: TSMC official website

There is not much time left for domestic car chips

For domestic automobile chips, the expansion of the production of large IDM chip manufacturers will bring severe and arduous challenges.

The main factor of this round of domestic car chip explosion is insufficient automobile chip supply, which has caused some domestic chip manufacturers to get some orders in the body, cockpit and other links, and some orders are met by working regulations.To put it bluntly, the order that international IDM can't eat is the opportunity of domestic automobile chip manufacturers, which is the so -called window period.

A report issued by the US consulting agency AlixPartners (Alix Partnership) pointed out that chip manufacturing is still a bottleneck of automotive production capacity, and it is expected that automobile chips will still be in short supply in 2024.However, by the end of 2024, the global automotive chip supply is expected to completely restore the normal state. The period for the development of domestic automobile chips may be closed in 2025.Coupled with the expansion of the production of large -use IDM plants today, the window period for the development of domestic automobile chips may be shorter than expected.

In the next few years, domestic automobile chip manufacturers need to do two things, one is to hurry up to improve their technical competitiveness, and the other is to deeply bind as much as possible with the large car manufacturers.