News

How to use silicon carbide to create a next -generation solid -state circuit breaker

- Source:Network finishing

- Release on:2024-03-06

Today, the performance advantages brought by silicon carbide (SIC) devices in electric vehicles (EV) and solar photovoltaic (PV) applications have been widely recognized.However, SIC's material advantages may also be used in other applications, including the field of circuit protection.This article will review the development of this field, while comparing the advantages and disadvantages of solid -state circuit breakers (SSCB) implemented by mechanical protection and use of different semiconductor devices.In the end, this article will also discuss why SIC solid -state circuit breakers are increasingly favored.

Protective power infrastructure and equipment

The power transmission and distribution system and sensitive equipment need to be properly protected to prevent damage due to long -term overload and short circuit.As the voltage used by electric power systems and electric vehicles is getting higher and higher, the possible maximum fault current is higher than ever before.In order to provide protection for these high current faults, we need super fast communication and DC circuit breakers.In the past, mechanical circuit breakers have always been the main choice of such applications. However, as work requirements are becoming more and more stringent, solid -state circuit breakers are becoming more and more popular.Compared with mechanical circuit breakers, solid -state circuit breakers have many advantages:

· Stability and reliability: The mechanical circuit breaker contains activity components, so it is relatively easy to be damaged.This means that they are easily damaged or accidentally disconnected by exercise, and during use, each reset will wear.In contrast, solid -state circuit breakers do not contain active components, so it is more stable and reliable, and it is not easy to cause accidental damage. Therefore, it can be repeatedly disconnected/closed.

· Temperature flexibility: The working temperature of the mechanical circuit breaker depends on its manufacturing materials, so there is a certain restriction in the working temperature.In contrast, the working temperature of the solid -state circuit breaker is higher and can be adjusted, so it can more flexibly adapt to different working environments.

· Remote configuration: The mechanical circuit breaker needs to manually reset manually after the trip, which may be very time -consuming and cost -effective, especially when multiple installation points are deployed on large -scale deployment, there may be hidden safety hazards.The solid circuit breaker can be remotely reset through wired or wireless connections.

· The switch speed is faster and does not generate an arc: the mechanical circuit breaker may produce larger arcs and voltage fluctuations when switching, enough to damage the load equipment.The solid -state circuit breaker adopts a soft start -up method to protect the circuit from the influence of these inductive voltage peaks and capacitive wave current, and the switching speed is much faster. It only takes a few milliseconds to cut the circuit when the failure occurs.

· Flexible current rated value: The solid -state circuit breaker has a programmable current rated value, while the mechanical circuit breaker has a fixed current rated value.

· Small size and lighter weight: Compared with mechanical circuit breakers, the solid circuit breaker is lighter and smaller.

The limitations of existing solid -state road breakers

Although the solid circuit breaker has multiple advantages compared to the mechanical circuit breaker, they also have some disadvantages, which include the voltage/current rated value, which is limited, the turnover loss is higher and the price is more expensive.Generally, for AC applications, solid -state circuit breakers are based on silicon -based flowers (TRIAC), and for DC systems, they are based on standard plane MOSFETs.TRIAC or MOSFET is responsible for achieving switching functions, while light isolation drives are used as control components.However, in the case of high output current, MOSFET -based high -current solid -state circuit breakers need to use heat sinks, which means that they cannot reach the same power density level as mechanical circuit breakers.

Similarly, solid -state circuit breakers implemented using the insulation grid bipolar crystal pipe (IGBT) also need to be heat sinks, because when the current exceeds dozens of amperers, the saturated voltage will cause excessive power loss.For example, when the current is 500 amp, the 2V voltage drop on IGBT will generate up to 1000W power loss.For the same power level, MOSFET needs to have about 4 m?As the voltage rated value of the device in electric vehicles develops towards 800V (or even higher), no single device can achieve this resistance level.Although the number can be theoretically connected by parallel devices, this approach will significantly increase the size and cost of the solution, especially when the two -way current needs to be processed.

Use the SIC power module to create the next -generation solid -state circuit breaker

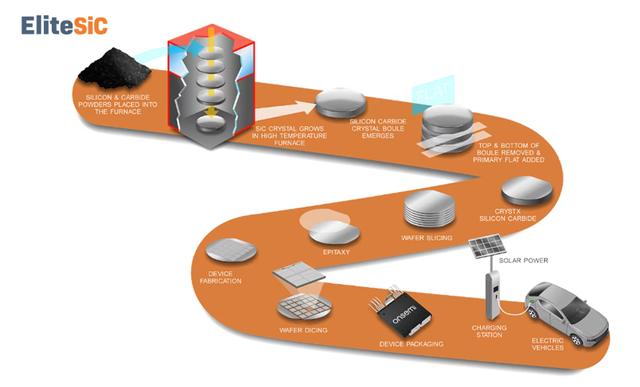

Compared with silicon chips, SIC chips can be reduced by up to ten times under the same rated voltage and drive resistance conditions.In addition, the switch speed of the SIC device is at least 100 times faster than that of silicon devices, and it can work at a peak temperature of more than twice as high as it.At the same time, SIC has excellent thermal conductivity, so it has better stability at high current levels.Ansonami uses these characteristics of SIC to develop a series of Elitesic power modules, which are low to 1.7m?These modules integrate two to six SIC MOSFETs in a single package.

Sintering chip technology (burning two independent chips in one package) can provide reliable product performance even at high power levels.Due to the fast switching behavior and high thermal guidance rate, such devices can quickly and safely "go to the card" (disconnect circuit) when the failure occurs, and prevent the current from flowing until normal working conditions.Such a module shows that it is increasingly integrated into multiple SIC MOSFET devices into a single package to achieve low -conductors and small sizes, thereby meeting the needs of actual circuit breaker applications.In addition, Ansonmei also provides Elitesic MOSFET and power modules with a voltage range of 650V to 1700V, so these devices can also be used to create solid -state circuit breakers suitable for single -phase and three -phase family, commercial and industrial applications.Ansonmei's SIC supply chain with vertical integration can provide nearly zero -deficiency products. These products have been comprehensive reliability testing and can meet the needs of solid -state circuit breaker manufacturers.

Figure 1: Ansonmei's complete end -to -end silicon carbide (SIC) supply chain

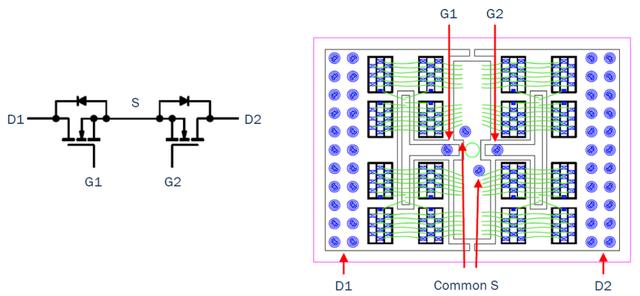

The figure below shows the modular implementation of the solid -state circuit breaker. Among them, it is connected to multiple 1200V SIC chips and multiple switches in parallel to achieve extremely low RDSON and optimized heat dissipation effects.These fully integrated modules below have optimized pins and layouts, which help reduce parasitic effects, improve switching performance, and shorten the failure response time.Ansonmi provides a variety of SIC module product portfolios. The rated voltage of the module is 650V, 1200V and 1700V, and some of the modules have a bottom plate, while others have no bottom plate to meet different application requirements and efficiency needs.

Figure 2: SIC B2B module suitable for solid -state circuit breakers -480VAC -200A

FIG

SIC technology and solid -state circuit breakers will develop together

The mechanical circuit breaker has low power loss and higher power density, and the current price is also lower than the solid -state circuit breaker.In addition, mechanical circuit breakers are easy to wear due to repeated use, and reset or replacement will generate expensive artificial maintenance costs.With the increasing popularity of electric vehicles, the market's demand for circuit breakers and SIC devices will continue to grow. Therefore, the cost competitiveness of this wide -ranging zone technology will increase, and its attractiveness to the solid -state circuit breaker solution will continue to increase.With the continuous progress of SIC technology and the resistance of the independent SIC MOSFET, the power loss of the solid -state circuit breaker will eventually reach the level comparable to the mechanical circuit breaker. At that time, power loss will no longer be a problem.The solid -state circuit breaker based on SIC devices has the advantages of fast switching speed, arc no arc, and zero maintenance, which can bring significant cost savings, so it will definitely become the mainstream choice for the market widely.